Add to Cart

Hello Everyone,

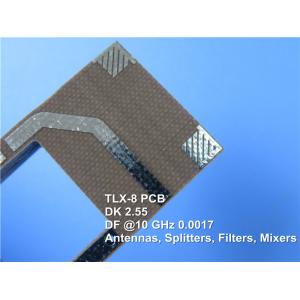

Today, we're going to talk about TLX high frequency PCB.

TLX is a series of PTFE fiberglass laminates launched by Taconic Company. It offers reliability in a wide range of RF applications. This material is versatile due to its 2.45 - 2.65 DK range. It is suitable for low layer count microwave PCBs.

Let's firstly see the advantages that we benefit from.

1. Dimensionally stable:

It can experience high level of vibration, such as space launch.

2. Excellent thermal properties:

It can experience high temperature exposure, such as working in engine modules.

3. Low and stable dielectric constant and tightly controlled DK.

Ranging 2.45 to 2.65 at tolerance +/-0.04

4. Low moisture absorption

Undergoing extreme severe environments, such as working at sea

5. Flame retardant grade, UL 94 V0

6. Low DF

TLX is ideal material for use in the application of following list due to its wide DK range and available thickness and copper cladding.

The typical applications are radar systems, antennas, mobile communications, mcrowave test equipment, microwave transmission devices, mixers, splitters, filters and combiners etc.

There’re TLX-0, TLX-9, TLX-8, TLX-7 and TLX-6 in TLX family. Often it’s used in single layer board, double layer board etc. Surface finish is mainly with bare copper, hot air level and immersion gold.

| PCB Capability | |

| PCB Material: | PTFE Fiberglass |

| TLX Family (Dielectric constant ±0.04) | TLX-0 (DK=2.45) |

| TLX-9 (DK=2.50) | |

| TLX-8 (DK=2.55) | |

| TLX-7 (DK=2.60) | |

| TLX-6 (DK=2.65) | |

| Layer count: | 1 Layer, 2 Layer, 4 Layer. |

| Copper weight: | 0.5oz, 1oz, 2oz |

| PCB thickness: | 0.5mm, 0.8mm, 1.0mm, |

| 1.5mm, 3.2mm | |

| PCB Size: | ≤400mm X 500mm |

| Surface finish: | Bare copper, HASL, ENIG, Immersion tin etc. |

The basic colour of TLX high frequency PCB is brown and black.

We specialize in providing you with prototype, small batches and mass production service.

If you have any requirements on this kind of PCB, please feel free to contact us.

Thank you for your reading.

Appendix: Data Sheet of TLX-8

| TLX-8 TYPICAL VALUES | |||||

| Property | Test Method | Unit | Value | Unit | Value |

| DK @10 GHz | IPC-650 2.5.5.3 | 2.55 | 2.55 | ||

| Df @1.9 GHz | IPC-650 2.5.5.5.1 | 0.0012 | 0.0012 | ||

| Df @10 GHz | IPC-650 2.5.5.5.1 | 0.0017 | 0.0017 | ||

| Dielectric Breakdown | IPC-650 2.5.6 | kV | >45 | kV | >45 |

| Moisture Absorption | IPC-650 2.6.2.1 | % | 0.02 | % | 0.02 |

| Flexural Strength(MD) | ASTM D 709 | psi | 28,900 | N/mm2 | |

| Flexural Strength(CD) | ASTM D 709 | psi | 20,600 | N/mm2 | |

| Tensile Strength(MD) | ASTM D 902 | psi | 35,600 | N/mm2 | |

| Tensile Strength(CD) | ASTM D 902 | psi | 27,500 | N/mm2 | |

| Elongation at Break(MD) | ASTM D 902 | % | 3.94 | % | 3.94 |

| Elongation at Break(CD) | ASTM D 902 | % | 3.92 | % | 3.92 |

| Young's Modulus(MD) | ASTM D 902 | kpsi | 980 | N/mm2 | |

| Young's Modulus(CD) | ASTM D 902 | kpsi | 1,200 | N/mm2 | |

| Young's Modulus(MD) | ASTM D 3039 | kpsi | 1,630 | N/mm2 | |

| Poisson's Ratio | ASTM D 3039 | 0.135 | N/mm | ||

| Peel Stength(1 oz.ed) | IPC-650 2.4.8 Sec.5.2.2(Thermal Stress.) | Ibs./linear inch | 15 | N/mm | |

| Peel Stength(1 oz.RTF) | IPC-650 2.4.8 Sec.5.2.2(Thermal Stress.) | Ibs./linear inch | 17 | N/mm | |

| Peel Stength(½ oz.ed) | IPC-650 2.4.8.3(Elevated Temp.) | Ibs./linear inch | 14 | N/mm | |

| Peel Stength(½ oz.ed) | IPC-650 2.4.8 Sec.5.2.2(Thermal Stress.) | Ibs./linear inch | 11 | N/mm | |

| Peel Stength(1 oz.rolled) | IPC-650 2.4.8 Sec.5.2.2(Thermal Stress.) | Ibs./linear inch | 13 | N/mm | 2.1 |

| Thermal Conductivity | ASTM F433/ASTM 1530-06 | W/M*K | 0.19 | W/M*K | 0.19 |

| Dimensional Stability(MD) | IPC-650 2.4.39 Sec.5.5(After Bake.) | mils/in. | 0.06 | mm/M | |

| Dimensional Stability(CD) | IPC-650 2.4.39 Sec.5.4(After Bake.) | mils/in. | 0.08 | mm/M | |

| Dimensional Stability(MD) | IPC-650 2.4.39 Sec.5.5(Thermal Stress.) | mils/in. | 0.09 | mm/M | |

| Dimensional Stability(CD) | IPC-650 2.4.39 Sec.5.5(Thermal Stress.) | mils/in. | 0.1 | mm/M | |

| Surface Resistivity | IPC-650 2.5.17.1 Sec.5.2.1(Elevated Temp.) | Mohm | 6.605 x 108 | Mohm | 6.605 x 108 |

| Surface Resistivity | IPC-650 2.5.17.1 Sec.5.2.1(Humidity Cond.) | Mohm | 3.550 x 106 | Mohm | 3.550 x 106 |

| Volume Resistivity | IPC-650 2.5.17.1 Sec.5.2.1(Elevated Temp.) | Mohm/cm | 1.110 x 1010 | Mohm/cm | 1.110 x 1010 |

| Volume Resistivity | IPC-650 2.5.17.1 Sec.5.2.1(Humidity Cond.) | Mohm/cm | 1.046 x 1010 | Mohm/cm | 1.046 x 1010 |

| CTE(X axis)(25-260℃) | IPC-650 2.4.41/ASTM D 3386 | ppm/℃ | 21 | ppm/℃ | 21 |

| CTE(Y axis)(25-260℃) | IPC-650 2.4.41/ASTM D 3386 | ppm/℃ | 23 | ppm/℃ | 23 |

| CTE(Z axis)(25-260℃) | IPC-650 2.4.41/ASTM D 3386 | ppm/℃ | 215 | ppm/℃ | 215 |

| Density(Specific Gravity) | ASTM D 792 | g/cm3 | 2.25 | g/cm3 | 2.25 |

| Td(2% Weight Loss) | IPC-650 2.4.24.6(TGA) | ℃ | 535 | ℃ | |

| Td(5% Weight Loss) | IPC-650 2.4.24.6(TGA) | ℃ | 553 | ℃ | |

| Flammability Rating | UL-94 | V-0 | V-0 | ||